Grain Screw Cleaning Machine

Brand Qiushi

Product origin Shenyang, Liaoning

Delivery time According to the difficulty of the project

Supply capacity According to the difficulty of the project

1. Our Steel Grain Discharge Screw Conveyor is equipped with a variety of safety protection devices to ensure the safety of operators and equipment.

2. Our Screw conveyor is highly adaptable and can clean various types of ore silos.

3. Our auger conveyor adopts a humanized operation interface, which can be easily controlled by the operator.

Introduction of sand auger conveyor:

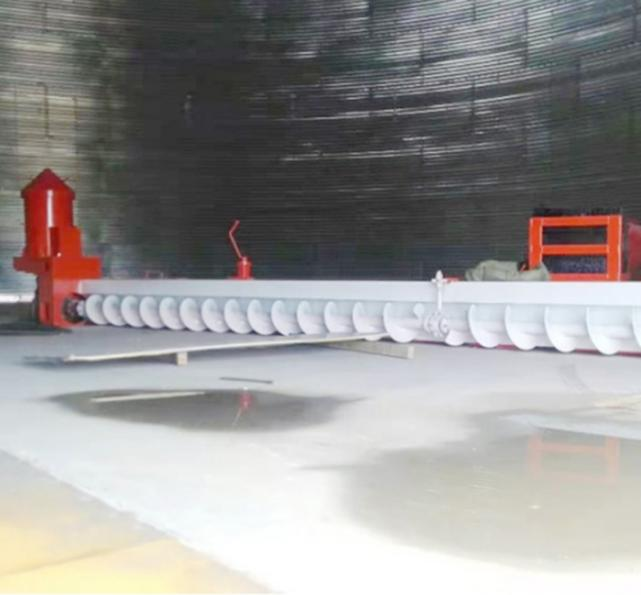

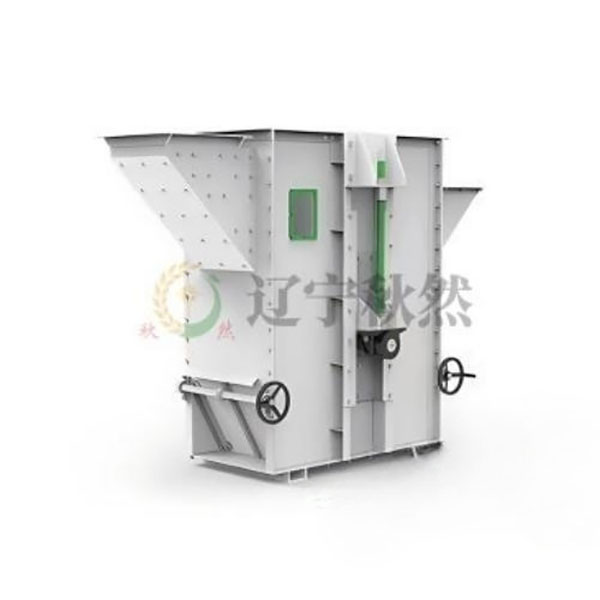

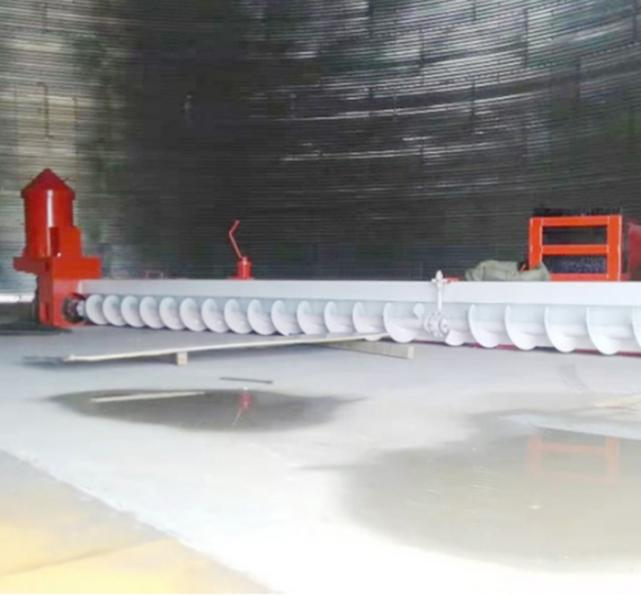

The sand auger conveyor is a special machine used to clean impurities and blockages on the coal bunker and transport belts, or to concentrate the remaining cargo in the hold for further unloading operations. Steel Grain Discharge Screw Conveyor has different types and functions according to different application fields and purposes. Screw conveyor usually consists of excavation mechanism, scraper transport mechanism and loading mechanism.

Advantages of sand auger conveyor:

The auger conveyor is specially designed to clean various types of ore silos. The sand auger conveyor can save a lot of human resources and reduce production costs through automation and intelligent technology. The use of Steel Grain Discharge Screw Conveyor improves the efficiency of ore warehouse cleaning, reduces the labor intensity of workers, reduces the loss and waste of ore, and the Screw conveyor improves the economic benefits of the mine.

Details of Grain Screw Cleaning Machine:

1. The auger conveyor is suitable for conveying bulk grain materials or loose materials. It makes circular motion around a fixed point. It is an ideal clearing equipment for realizing automated mechanical discharging of large and medium-sized cylindrical silos.

2. There are two types of sand auger conveyor, tire-type warehouse clearing machine and track-type warehouse cleaning machine.

3. Steel Grain Discharge Screw Conveyor has a wide rotation diameter range: 12m ~ 36m.

4. Conveying capacity: 20t/h~450t/h.

Application of Grain Screw Cleaning Machine:

Screw conveyor is a brand-new technology that solves the problem of clearing underground water silos in coal mines and realizes automatic clearing and recovery of coal slime. The auger conveyor is very effective and can quickly clean up silt and impurities to ensure mine safety and normal operation of equipment. The sand auger conveyor is convenient and fast, can be remotely controlled and automatically operated, and the scraper and chain design are convenient for transportation and installation. Steel Grain Discharge Screw Conveyor has important practical significance and value.

Why choose our company:

Our company specializes in R&D and manufacturing of Screw conveyor equipment. We have a technical team and advanced equipment to provide high-quality products. We can provide personalized customization services and customize appropriate models and specifications according to customer needs and site conditions. Adhere to the principle of reasonable pricing, provide cost-effective products, and help customers reduce costs and improve efficiency.

About us

Liaoning Qiushi Vertical Silo Equipment Engineering Co., Ltd. is located in Shenyang with a registered capital of 20 million yuan. It is engaged in steel warehouses, steel structures, civil construction, drying towers and electrical equipment installation. It has complete sets of equipment and 260 employees, with technical strength Strong and professional, it can undertake the construction of prefabricated steel silos, spiral steel silos of 5-15,000 tons, drying towers of 100-1,500 tons and related equipment.

Our company has a professional construction team and provides customized products and services. Our construction team is experienced and able to meet the individual needs of our customers. Whether in the design or implementation stages, we are committed to providing our customers with high-quality, customized solutions. You are welcome to cooperate with us and let us work together to create the ideal product to meet your unique needs.